Introduction

The glass mosaic industry has witnessed significant progress with the advent of high-temperature inkjet printing on glass. As a well-established manufacturer in the Chinese glass mosaic industry, MEIMA Mosaic has always been dedicated to research and development of new products and techniques. The introduction of glass high-temperature inkjet printing technology allows for the printing of any pattern or color on the bottom or surface of glass, followed by high-temperature firing, resulting in a myriad of exquisite designs and vibrant hues. In this blog post, we will delve into the world of glass high-temperature inkjet printing, exploring its applications, benefits, and impact on the construction industry.

The Evolution of Glass Mosaic Production

Traditionally, the production of glass mosaics involved manual craftsmanship, where skilled artisans meticulously assembled individual glass pieces to create intricate patterns. While this method allowed for beautiful designs, it was time-consuming and limited in terms of pattern complexity and color options. As technology advanced, the glass mosaic industry sought innovative techniques to overcome these limitations and cater to the evolving demands of architects, designers, and consumers.

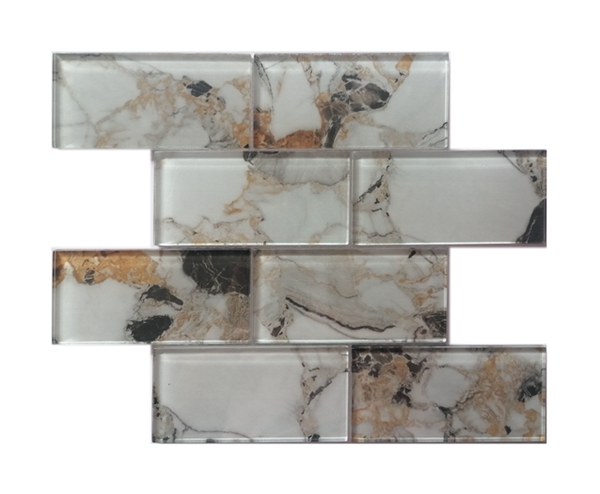

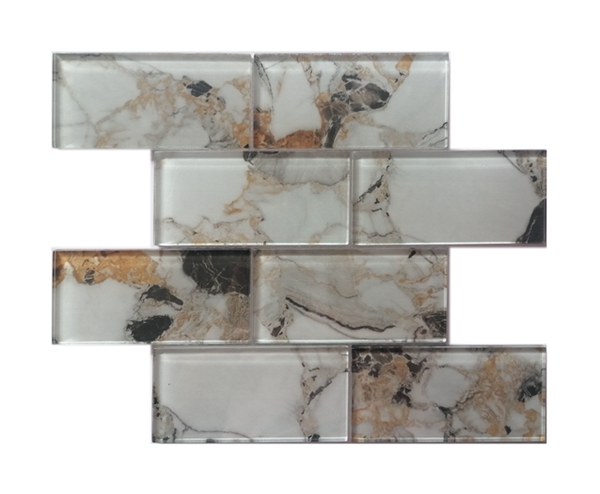

A pack of grey and black mixed Inkjet Glass Mosaic Tile in Rectangle shape

The Emergence of High-Temperature Inkjet Printing on Glass

High-temperature inkjet printing on glass emerged as a breakthrough technology, revolutionizing the glass mosaic industry. By combining the precision of inkjet printing with the durability of high-temperature firing, this technique opened up a world of creative possibilities. It allows for the direct application of any pattern or color onto glass, eliminating the need for manual assembly and expanding the design repertoire to virtually limitless options.

Working Principles of Glass High-Temperature Inkjet Printing

The process of glass high-temperature inkjet printing involves several key steps. First, a specialized ink, formulated to withstand high temperatures, is loaded into the printer. The printer then accurately deposits the ink onto the glass substrate, following the desired pattern. Once the ink is applied, the glass is subjected to a high-temperature firing process, typically in a kiln, which fuses the ink with the glass, resulting in a permanent, durable, and visually captivating design.

Applications of Glass High-Temperature Inkjet Printing

Glass high-temperature inkjet printing finds applications across various sectors, ranging from architectural projects to interior design and art installations. Here are some notable applications:

Architectural Facades: Glass panels featuring intricate patterns and vibrant colors can be used to create eye-catching facades, adding a unique visual element to buildings.

Interior Design: Glass mosaic tiles produced through high-temperature inkjet printing offer endless design possibilities for kitchens, bathrooms, swimming pools, and other interior spaces, enabling personalized and visually striking designs.

Art Installations: Artists can leverage this technology to create stunning glass artworks, pushing the boundaries of creativity and expression.

Benefits of Glass High-Temperature Inkjet Printing

The adoption of glass high-temperature inkjet printing brings several benefits to the glass mosaic industry:

Design Flexibility: The technology enables the production of highly intricate designs, complex patterns, and customized motifs, meeting the demands of architects and designers seeking unique and personalized solutions.

Color Reproduction: High-temperature inkjet printing ensures accurate color reproduction, allowing for vibrant and rich color palettes that were previously challenging to achieve with traditional glass mosaic techniques.

Efficiency and Cost-Effectiveness: The automated nature of inkjet printing reduces production time and labor costs, enabling manufacturers to deliver projects more efficiently.

Durability: The high-temperature firing process ensures that the printed patterns and colors are permanently fused with the glass, providing long-lasting durability and resistance to wear, fading, and discoloration.

The Impact on the Construction Industry

The introduction of glass high-temperature inkjet printing has had a significant impact on the construction industry, particularly in the realm of architectural design and interior decoration. Let's explore some key aspects of this impact:

Architectural Innovation: Glass high-temperature inkjet printing has opened up new avenues for architectural innovation, allowing architects to incorporate intricate patterns, custom designs, and vibrant colors into building facades. This technology has transformed glass from a mere functional material to a medium for artistic expression, enabling architects to create visually stunning structures that stand out in the urban landscape.

Customization and Personalization: With the ability to print any pattern or color on glass, high-temperature inkjet printing offers unprecedented customization and personalization options. Architects and interior designers can now tailor their designs to suit the unique preferences and branding requirements of their clients. This level of customization enhances the overall aesthetics of the space, creating a distinctive and memorable environment.

Sustainable Solutions: Glass, as a material, is known for its sustainability attributes. It is recyclable, non-toxic, and allows for the efficient use of natural light. The introduction of high-temperature inkjet printing further enhances the sustainability of glass mosaic production. By eliminating the need for additional materials, such as adhesives or pigments, the technology reduces waste and environmental impact, aligning with the growing demand for eco-friendly construction practices.

Market Competitiveness: As high-temperature inkjet printing becomes more prevalent in the glass mosaic industry, manufacturers who adopt this technology gain a competitive edge. The ability to offer a wide range of design options, faster production times, and superior color accuracy positions these manufacturers as leaders in the market. This not only attracts architects, designers, and developers seeking innovative solutions but also contributes to the growth and success of the manufacturers themselves.

Conclusion

Glass high-temperature inkjet printing represents a significant advancement in the glass mosaic industry. Its ability to print intricate patterns and vibrant colors on glass surfaces opens up a realm of design possibilities for architects, interior designers, and artists. The technology not only enhances the aesthetic appeal of architectural projects but also offers customization, durability, and sustainability benefits. As the construction industry continues to evolve, embracing innovative techniques like high-temperature inkjet printing ensures that glass mosaic manufacturers stay at the forefront of design and fulfill the growing demands of the market.